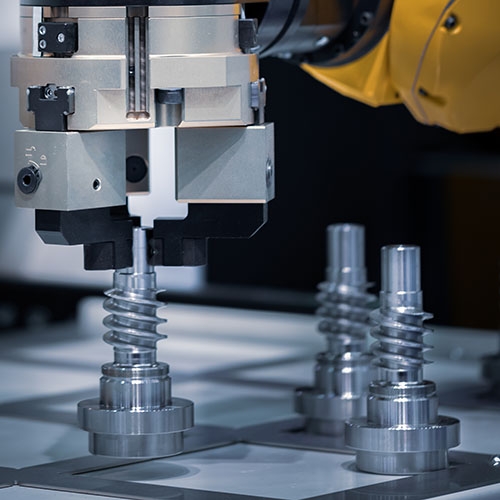

As more manufacturers invest in smart automation and robotics, the need for adaptable, durable, and precision-engineered material handling components has never been greater. One of the most versatile and critical components in automated environments is the wire basket. Custom wire baskets support robotic arms, conveyors, and pick-and-place systems by providing structure, flow, and protection for parts and materials. At Salco Engineering & Manufacturing, we specialize in designing and fabricating custom wire baskets built specifically for robotics integration.

Why Custom Wire Baskets Matter in Robotics

Standard baskets often fall short when introduced into highly automated settings. Every robotics system is designed around a specific workflow, timing sequence, and spatial layout. If the containers used in that system aren’t optimized for compatibility, they can lead to misalignment, part damage, or slowdowns in processing time.

Custom wire baskets can be tailored for:

Robotic arm gripping and stacking

Compatibility with automation cells

Precise part orientation and separation

Protection from abrasion, contamination, or impact

Consistency for repeatability in automation

Salco’s wire baskets are engineered for automation from the start, considering everything from mesh size to lifting points to ensure perfect synergy between equipment and basket.

Applications of Wire Baskets in Robotics and Automation

Wire baskets play a wide range of roles in automated environments, including:

Parts Transport and Staging

Whether used for moving components from one cell to another or temporarily storing them in a staging area, wire baskets keep parts organized and accessible for robotic systems. The baskets’ open design promotes airflow and visibility, helping sensors or cameras locate items accurately.

Pick-and-Place Operations

Custom wire baskets can be designed with dividers, contours, or custom cutouts that allow robotic grippers to accurately and reliably pick up items. In industries like electronics or precision machining, small tolerances require precise alignment—something custom baskets help achieve.

Post-Processing and Parts Washing

Many automated systems rely on wire baskets for washing, coating, or drying components. Our stainless steel and electropolished baskets are ideal for ultrasonic cleaning, chemical rinse cycles, or high-heat drying environments. Learn more about our [parts washing baskets for industrial cleaning](https://www.salcoeng.com/parts-washing-baskets-for-industrial-cleaning/) or [stainless steel ultrasonic wash baskets](https://www.salcoeng.com/stainless-steel-ultrasonic-wash-baskets/).

Automated Storage and Retrieval Systems (ASRS)

Custom baskets designed to fit within ASRS racking or trays can reduce jamming, allow for faster retrieval, and optimize space within high-density storage systems.

Benefits of Salco’s Custom Wire Baskets for Automation

Durability for High-Cycle Use

Robotic systems run thousands of cycles daily, and the material handling baskets must keep up. Salco fabricates wire baskets from high-grade stainless or carbon steel, often coated with [zinc plating](https://www.salcoeng.com/how-zinc-plating-protects-industrial-steel-baskets-and-wire-products/) or [nylon](https://www.salcoeng.com/nylon-coating-vs-other-finishes-protective-coatings-for-wire-baskets/) for added protection and longevity.

Consistency for Precision Robotics

Automation relies on repeatability. Each basket Salco produces is built to tight tolerances and undergoes stringent quality control to ensure consistency from one basket to the next—minimizing variability and downtime in your robotic systems.

Customizable for Any System

Need recessed handles? Stackable frames? Mesh sizes that match your part dimensions? We work with engineers, integrators, and automation specialists to deliver fully customized designs that suit your facility and workflow.

Contamination Control

Especially in the automotive, aerospace, and medical sectors, cleanliness is critical. Wire baskets used in robotic work cells can be [electropolished](https://www.salcoeng.com/electropolishing-manufacturing-baskets-key-benefits/) or made from passivated stainless steel to support cleanliness and prevent part contamination.

Industries Benefiting from Robotics-Ready Wire Baskets

Our custom automation-ready baskets are used in a wide range of industries, including:

Automotive manufacturing (engine components, battery modules)

Aerospace part washing and assembly

Medical device sterilization and kitting

Electronics assembly lines

Metal stamping and fabrication

Explore more about our work in the automotive and aerospace sectors.

Design Collaboration with Salco

Our team of designers and engineers uses SolidWorks to generate accurate models and simulations before production. We also offer 3D printing for rapid prototyping and design validation.

Whether you’re retrofitting an existing system or launching a new robotic cell, Salco will work with your team to deliver a wire basket solution that aligns with your operational goals and robotic requirements.

Get Started with Custom Robotics-Compatible Wire Baskets

Custom wire baskets can significantly improve performance, safety, and efficiency in automated facilities. Salco Engineering & Manufacturing offers precision-crafted wire baskets specifically designed for robotics applications across industrial sectors.

Ready to start your project? Contact us today for a free quote and discover how our custom wire baskets can enhance your robotics workflow. Let us help you move smarter with automation-ready material handling solutions.