Dunnage Inserts

If you’re looking for a custom-designed dunnage insert for your manufacturing, storage, or shipping needs, Salco Engineering and Manufacturing has you covered.

Our tote inserts are custom-made to fit your parts perfectly, ensuring that they are protected during transport, storage, and handling. We use the latest technology and equipment to design and manufacture dunnage inserts that are not only functional, but also durable and long-lasting. Whether you need a single dunnage insert or hundreds, we can accommodate your needs.

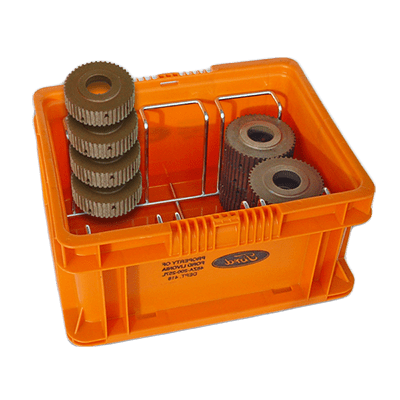

Our wire inserts are made to fit your particular part and placed in standard plastic totes. This yields a lighter weight container that is stackable and returnable. Request a quote today for your next project.

Ready for a Quote?

Salco can quote projects of all shapes and sizes. If you have questions about our services, please click here to contact us. Someone from our team will be happy to assist you.

What is Returnable Plastic Dunnage?

Returnable dunnage refers to plastic totes that are often used in industries such as automotive, aerospace, and medical. The primary benefits include stacking, part protection, and lighter shipping weight. Salco adds custom steel wire dividers or part holding inserts to standard plastic totes to keep your parts secure.

Benefits of Custom Inserts

Dunnage inserts are essential for protecting your parts during transport and storage. Custom dunnage inserts offer several benefits, including:

Enhanced Protection

Custom-designed dunnage inserts provide a precise fit for your specific parts, ensuring that they are securely held in place and protected from damage. This level of protection is simply not possible with one-size-fits-all solutions.

Improved Efficiency

Custom dunnage inserts can help streamline your production and logistics processes, allowing you to pack, transport, and unpack your parts more efficiently. This can lead to improved productivity, reduced waste, and lower costs.

Better Organization

With custom dunnage inserts, you can organize your parts more effectively, reducing the risk of damage, loss, or misplacement. This can help improve overall quality and reduce the risk of errors or defects.

Materials and Design Options

At Salco Engineering and Manufacturing, we offer a wide range of materials and design options to meet your specific needs. Our experienced team will work closely with you to understand your requirements and design a custom dunnage insert that is tailored to your unique needs.

Why Choose Salco Engineering and Manufacturing?

At Salco Engineering and Manufacturing, we have over 60 years of experience in designing and manufacturing custom material handling products and steel fabrication services. We have a proven track record of delivering high-quality solutions that meet our clients’ unique needs and requirements.

We use the latest technology and equipment to design and manufacture our custom dunnage inserts, ensuring that they meet the highest standards of quality and durability.