Automotive manufacturing trends. The automotive manufacturing landscape is continually evolving, driven by technological advancements, shifting consumer preferences, and the industry’s commitment to sustainability. Staying abreast of automotive manufacturing trends is crucial for businesses aiming to remain competitive and responsive to changing demands. In this blog post, we delve into the latest automotive manufacturing trends and explore how the industry is adapting to these transformative changes.

Dynamics of Automotive Manufacturing Trends

Embracing Technological Advancements

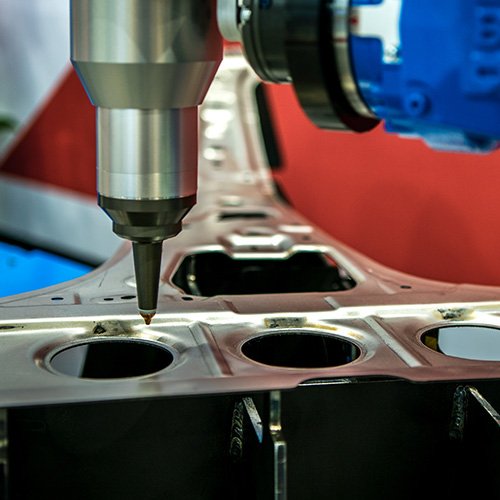

One of the key trends shaping automotive manufacturing is the rise of connected and autonomous vehicles. As the industry moves towards smart, self-driving cars, manufacturers are integrating advanced technologies such as sensors, artificial intelligence, and machine learning into their production processes. This not only enhances vehicle performance but also requires a more sophisticated approach to manufacturing.

Digitalization in the Supply Chain

Automotive manufacturers are increasingly adopting digital technologies to streamline their supply chain processes. From predictive maintenance to real-time tracking of components, digitalization is improving efficiency and reducing downtime. This shift towards Industry 4.0 principles is revolutionizing the way vehicles are produced, making the manufacturing process more agile and responsive.

Cleanliness and Contamination Control

The automotive industry places a premium on cleanliness in facilities and parts to prevent contamination issues down the line. Clean manufacturing environments are essential for ensuring the quality and reliability of automotive components. This has led to a growing demand for material handling solutions that adhere to stringent cleanliness standards.

Meeting the Challenge: Salco’s Stainless Steel Solutions

Stainless Steel Carts and Baskets

In response to the automotive industry’s demand for cleaner facilities and parts, Salco Engineering provides innovative material handling solutions, including stainless steel carts and baskets. Stainless steel is the material of choice for automotive manufacturers striving for cleanliness and durability.

Benefits of Stainless Steel

- Hygienic Properties: Stainless steel is inherently resistant to corrosion and bacteria, making it an ideal material for environments where cleanliness is paramount.

- Durability: Stainless steel is robust and can withstand the rigorous demands of automotive manufacturing processes, ensuring a longer lifespan for carts and baskets.

- Easy Cleaning: The smooth surface of stainless steel facilitates easy cleaning and sterilization, contributing to maintaining a contaminant-free manufacturing environment.

Adaptable Solutions for Changing Needs

Salco Engineering understands the dynamic nature of the automotive manufacturing industry. Customization is at the core of our solutions, ensuring that our stainless steel baskets and carts meet the specific requirements of each client. Whether it’s adapting to changes in production processes or accommodating unique spatial constraints, Salco’s solutions are designed to be versatile and adaptable.

Conclusion

In conclusion, the automotive manufacturing landscape is undergoing a significant transformation, driven by technological advancements and an increased focus on cleanliness and contamination control. Staying ahead in this dynamic environment requires manufacturers to embrace these trends and invest in solutions that align with the industry’s evolving needs.

Salco Engineering stands at the forefront of meeting these challenges, providing stainless steel carts, baskets, and material handling products that not only adhere to the highest cleanliness standards but also offer the durability and adaptability required in the fast-paced world of automotive manufacturing. As the industry continues to evolve, Salco remains committed to delivering cutting-edge solutions that empower automotive manufacturers to thrive amidst change.