As the electric vehicle (EV) industry continues to grow rapidly, manufacturers are faced with the challenge of maintaining the highest quality standards for EV components. Ensuring these components are clean and free from contaminants is crucial for optimal performance and safety. One effective solution that has gained popularity in the EV automotive industry is the use of custom stainless steel baskets for component cleaning. In this article, we will explore the advantages and benefits of employing these specialized baskets in the EV manufacturing process.

Precision Cleaning in the EV Industry

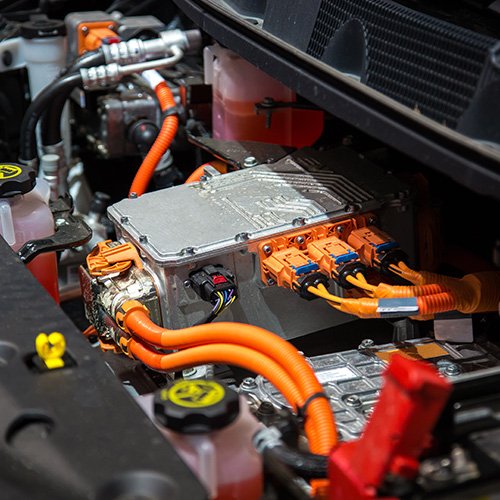

Electric vehicles are driven by complex systems, including sensitive electrical and mechanical components. The efficiency and longevity of these components depend on their cleanliness during the manufacturing process. Even the smallest contaminants can lead to performance issues, premature wear, and potential safety hazards. As a result, manufacturers must prioritize precision cleaning to meet the industry’s stringent standards.

The Role of Custom Stainless Steel Baskets

Custom stainless steel baskets have emerged as a reliable and efficient solution for cleaning EV components. These baskets are designed to cater to the specific requirements of manufacturers, offering a range of benefits that contribute to enhanced cleaning processes and better overall outcomes.

Tailored Fit for Different Components

One of the primary advantages of custom stainless steel baskets is their ability to accommodate a wide variety of EV components. These baskets can be tailored to perfectly fit the shape and size of various parts, ensuring that each item is securely held during the cleaning process. As a result, components are thoroughly cleaned without the risk of damage or contamination.

Optimal Cleaning Efficiency

The design of custom stainless steel baskets allows for maximum exposure of the components to cleaning agents and processes. This leads to improved cleaning efficiency, as the baskets facilitate proper circulation of cleaning fluids around the parts, effectively removing all traces of contaminants. Consequently, manufacturers can achieve higher throughput and maintain consistent cleaning quality.

Corrosion Resistance and Longevity

Stainless steel is renowned for its exceptional corrosion resistance, making it an ideal material for use in harsh cleaning environments. Custom stainless steel baskets can withstand exposure to various cleaning solutions, ensuring longevity and cost-effectiveness. Manufacturers can rely on these baskets for long-term use, reducing the need for frequent replacements.

Enhanced Safety and Contamination Control

Maintaining a clean and contaminant-free manufacturing environment is critical for producing reliable EV components. Custom stainless steel baskets offer excellent contamination control, preventing particles from entering the cleaning process and adhering to the components. This feature minimizes the risk of defects and improves the overall quality of the finished products.

Sustainable Cleaning Solutions for EV Manufacturing

In addition to their technical advantages, custom stainless steel baskets contribute to sustainable manufacturing practices within the EV industry. By using these durable and reusable baskets, manufacturers can reduce waste generation associated with single-use containers or disposable cleaning solutions. This environmentally friendly approach aligns with the green ethos of the EV market, where sustainability is a key concern.

Cost-Effectiveness and Long-Term Savings

Investing in custom stainless steel baskets for EV component cleaning offers substantial long-term savings for manufacturers. Although the initial investment may be higher compared to standard cleaning equipment, the durability and longevity of these baskets offset the cost. Manufacturers can rely on these baskets for years, reducing the need for frequent replacements and lowering operational expenses over time.

Regulatory Compliance and Quality Assurance

The EV automotive industry is subject to strict regulatory standards to ensure the safety and reliability of vehicles. Utilizing custom stainless steel baskets for component cleaning helps manufacturers comply with these regulations by ensuring consistent cleanliness and quality. This not only enhances the reputation of the manufacturer but also builds trust among customers and stakeholders.

EV Component Cleaning

As the demand for electric vehicles continues to rise, manufacturers must prioritize the quality and cleanliness of EV components. Custom stainless steel baskets have emerged as a reliable and efficient solution for precision cleaning, offering tailored fit, optimal efficiency, corrosion resistance, and contamination control. By incorporating these specialized baskets into the manufacturing process, EV component manufacturers can achieve higher levels of performance, safety, and sustainability while enjoying long-term cost savings and regulatory compliance. As the EV industry evolves, custom stainless steel baskets will undoubtedly remain a crucial tool in maintaining the highest standards of component cleanliness and ensuring the success of electric vehicles on the roads of the future.