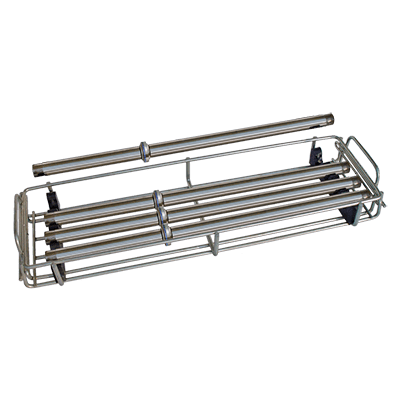

Metal baskets for automotive parts are crucial in the manufacturing process of gears and other components. These baskets are designed to hold the gears securely in place, preventing damage and ensuring consistent, high-quality results. In this article, we will discuss the importance of metal baskets in the automotive gear manufacturing process and provide some key considerations to keep in mind when selecting a basket for your needs.

The Role of Metal Baskets in Automotive Gear Manufacturing

Metal baskets play a critical role in the automotive gear manufacturing process. During production, gears must be held securely in place to prevent damage and ensure precision. A well-designed basket can provide the necessary support and protection to achieve high-quality results.

Key Considerations for Selecting Metal Baskets

When selecting steel baskets for your automotive gear manufacturing process, there are several key considerations to keep in mind.

Material Selection

The choice of material is an important consideration when selecting a metal basket. The material used will impact the basket’s durability, resistance to corrosion, and overall performance. Stainless steel is a popular choice due to its durability and resistance to corrosion, making it ideal for use in harsh manufacturing environments. Carbon steel is another popular option, providing high strength and durability, as well as resistance to heat and abrasion. Aluminum is a lightweight material that offers excellent resistance to corrosion and is ideal for use in processes where weight is a concern.

Customization Options

Customization options are also an essential consideration when selecting a metal basket for your automotive gear manufacturing needs. Every manufacturing process is unique, and customizing a basket can help ensure that it meets your specific requirements. Customization options include the size and shape of the basket, as well as the type of wire mesh used. Different mesh sizes and patterns can be used to ensure that the gears are held securely in place, while still allowing for proper airflow and fluid circulation during the manufacturing process.

Quality Control

Quality control is critical when selecting metal baskets for automotive gear manufacturing. A well-designed basket can help to prevent damage and ensure consistent results, but it must also be manufactured to exacting standards to ensure that it meets your needs. Working with a reputable manufacturer with a proven track record of quality can help to ensure that you receive the best possible product.

Conclusion

In conclusion, metal baskets are an essential component in the automotive gear manufacturing process. When selecting a basket, material selection, customization options, and quality control are all critical considerations. By working with an experienced manufacturer that specializes in automotive gear manufacturing, you can ensure that you receive a high-quality basket that meets your unique needs and delivers consistent, reliable results.