Stainless steel carts are essential tools in modern industrial environments. Their durability, cleanability, and structural strength make them ideal for manufacturing facilities, warehouses, laboratories, cleanrooms, and food production plants. Because stainless steel resists corrosion, supports heavy loads, and maintains hygiene standards far better than other materials, these carts have become a go-to solution for environments where efficiency and sanitation matter most.

Beyond simple transport, stainless steel carts play a key role in material handling, equipment organization, workflow optimization, and contamination control. Whether used as mobile storage, workstations, or transport carts, they improve productivity and support a safer, cleaner facility-wide process.

Industrial Uses for Stainless Steel Carts

Material Handling and Workflow Support

Stainless steel carts are widely used for material handling in industries such as automotive manufacturing, general machining, and distribution environments. Their strength allows workers to move heavy parts and components safely and efficiently throughout the production floor. Many facilities pair stainless carts with specialized equipment such as pneumatic lift workstations to reduce ergonomic strain and streamline part movement.

These carts also excel in contamination-sensitive areas like food processing plants or cleanrooms. Stainless steel’s smooth, non-porous surface prevents debris buildup and supports rigorous sanitation standards.

On-Floor Storage and Organization

Stainless steel carts double as mobile storage units for tools, fixtures, raw materials, and finished components. Their corrosion resistance ensures stored items remain protected in environments that may expose equipment to moisture, chemicals, or temperature fluctuations. Operations such as laboratories and pharmaceutical facilities rely on stainless carts because they prevent contamination and maintain strict cleanliness requirements.

Facility Transport and Logistics

Transporting materials through large facilities becomes more efficient with stainless steel carts. They support repetitive movement between workstations, shipping areas, wash zones, and assembly points. Industries that utilize custom industrial carts often include stainless steel variants for transporting sensitive components without risk of contamination.

Food Service and Food Production

Stainless steel is the gold standard in commercial kitchens, bakeries, and food processing plants. These carts withstand constant cleaning, hot environments, and frequent loading and unloading of ingredients or finished products. Many bakeries integrate stainless carts with existing equipment such as bakery storage racks to maintain efficient and hygienic workflows.

Hospitality and Facility Services

In hotels, banquet halls, and event spaces, stainless steel carts are used for transporting linens, dishes, supplies, and equipment. Their sleek appearance enhances the professional look of front-of-house and back-of-house operations.

Manufacturing and Assembly

Manufacturing plants rely on stainless carts for storing and moving parts, tools, and fixtures involved in assembly processes. In high-precision environments—such as pharmaceutical or medical device manufacturing—stainless steel carts help maintain sterile conditions and prevent contamination during part transfer and staging.

Healthcare Facilities

Healthcare environments require carts that are easy to sanitize and resistant to bacteria. Stainless steel medical carts transport supplies, equipment, and instruments in clinics, hospitals, and surgical environments. Their construction helps maintain patient safety and supports infection-control protocols.

Benefits of Stainless Steel Carts

Exceptional Durability

Stainless steel carts withstand heavy use in demanding industrial environments. Their resistance to rust, dents, and corrosion allows them to outperform plastic or aluminum alternatives, even in washdown or chemical-exposed areas.

Flexible and Customizable Designs

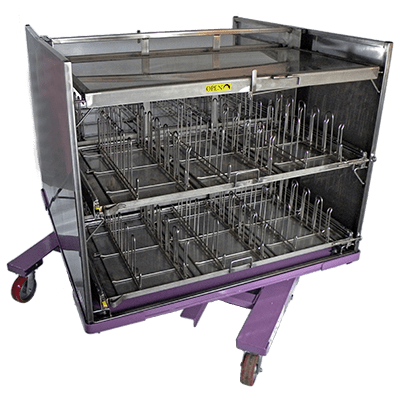

Many facilities customize their stainless steel carts to support unique workflows. Custom options may include tiered shelving, drawer systems, containment pans, ergonomic handles, divider systems, and compatibility with specialized equipment. When operations require custom configurations, many companies turn to tailored solutions such as custom steel carts that integrate seamlessly into their processes.

Easy to Clean and Sanitize

Stainless steel’s non-porous surface resists bacteria and pathogens. This makes stainless carts ideal for industries where hygiene, sanitation, or product purity are essential. Cleaning is quick and consistent, reducing downtime and supporting industry compliance.

Cost-Effective Over Time

Although stainless steel carts may have a higher upfront cost, their long lifespan and low maintenance requirements make them a cost-effective investment. They rarely require repair or replacement, helping facilities reduce long-term equipment expenses.

Customization Options for Stainless Steel Carts

Size, Shape, and Capacity

Carts can be fabricated in various dimensions to support tight aisles, heavy loads, or specific workflow requirements. Custom sizing helps maximize floor space and improve efficiency.

Functional Accessories

Optional accessories can include adjustable shelving, locking casters, push handles, tool brackets, and top work surfaces. These additions help tailor the cart to specific operational needs.

Material Variations

While stainless steel is preferred, some applications may benefit from mixed-material designs incorporating aluminum or carbon steel. Hybrid configurations are commonly used in environments balancing weight requirements and cost considerations.

Environmental Advantages of Stainless Steel

Stainless steel is 100% recyclable, making stainless steel carts an environmentally responsible choice. Facilities aiming to reduce their environmental impact appreciate the material’s long lifecycle and ability to be reclaimed rather than discarded. Sustainable equipment choices support broader green initiatives across manufacturing, warehousing, and commercial operations.

Improving Efficiency with Stainless Steel Carts

When combined with broader material handling solutions, stainless steel carts can greatly improve efficiency, reduce ergonomic strain, and support cleaner, safer workflows. Industries using cart-based strategies often integrate them with storage systems, part wash processes, or custom dunnage inserts to protect sensitive components during movement.

Enhance Your Facility with High-Quality Stainless Steel Carts

Stainless steel carts offer unmatched durability, cleanliness, and adaptability across multiple industries. Whether used for transport, storage, assembly, or sanitation-critical tasks, they help facilities maintain efficiency and meet operational demands.

If you’re ready to improve your workflow with high-quality stainless steel carts or need help selecting the right solution for your facility, contact Salco Engineering. Our team provides decades of experience in designing and fabricating custom material handling products tailored to your exact needs.