3D printing has become a powerful force in modern manufacturing, transforming how companies design, prototype, and produce components. Once considered a niche technology, industrial 3D printing is now widely adopted across automotive, aerospace, medical, and general manufacturing sectors. As accessibility and material performance continue to improve, manufacturers are increasingly using additive manufacturing to reduce lead times, control costs, and improve product development cycles.

Industry adoption continues to accelerate, with industrial companies embracing 3D printing at an expected compound annual growth rate of approximately 17 percent. This growth reflects the technology’s ability to solve real-world manufacturing challenges, particularly in prototyping, tooling, and low-volume production.

Why Manufacturers Are Turning to 3D Printing

Traditional manufacturing methods often require long lead times, expensive tooling, and limited design flexibility. 3D printing removes many of these constraints by building parts layer by layer directly from digital models. This approach allows manufacturers to iterate faster, validate designs earlier, and move from concept to production with greater confidence.

Companies like Salco Engineering & Manufacturing integrate 3D printing into their design and prototyping services to help clients reduce risk and accelerate development before committing to full-scale fabrication.

Five Key Advantages of 3D Printing in Manufacturing

Rapid Prototyping and Faster Development Cycles

One of the most valuable benefits of 3D printing is the ability to produce prototypes in hours instead of weeks. Engineers can quickly create physical parts to evaluate form, fit, and function early in the design process. This speed allows teams to identify issues sooner and make improvements before costly tooling or production steps begin.

Compared to machined prototypes, 3D printed parts are often significantly faster and more cost-effective to produce, especially during early-stage development.

Greater Design Flexibility and Iteration

3D printing enables design freedom that traditional manufacturing methods cannot easily achieve. Complex geometries, internal features, and custom shapes can be produced without additional tooling or setup changes.

Even after an initial prototype is approved, design changes can be implemented quickly by updating the digital model. This flexibility allows manufacturers to refine products continuously and avoid being locked into designs too early in the process.

Improved Fit, Function, and Process Validation

Physical prototypes created through 3D printing are ideal for validating fit and function within real production environments. Manufacturers can test how parts interact with assemblies, fixtures, or material handling systems before production begins.

3D printed go/no-go gauges, assembly aids, and test fixtures allow quality teams to verify tolerances and performance without extensive measuring or inspection processes. These tools help reduce errors and improve consistency once parts move into production.

Fast and Cost-Effective Tooling Fixtures

Beyond prototyping, 3D printing is widely used to create custom tooling, fixtures, and manufacturing aids. These include assembly fixtures, positioning guides, inspection tools, and ergonomic supports used directly on the shop floor.

High-performance materials such as ULTEM polyetherimide provide excellent thermal stability, chemical resistance, and dimensional accuracy. This makes them suitable for demanding industrial environments where traditional plastic tools would fail. Salco frequently incorporates 3D printed fixtures alongside custom fabrication processes such as steel fabrication and welding to support efficient production workflows.

Wide Range of Industrial Material Options

Modern industrial 3D printers support a growing range of materials designed for strength, durability, and performance. Common materials include ASA, Nylon 12, and ULTEM 1010, each selected based on application requirements.

These materials allow manufacturers to produce parts that withstand heat, chemicals, mechanical stress, and repeated use. In many cases, 3D printed components can be used directly in production environments rather than only as prototypes.

How 3D Printing Supports Lean Manufacturing

3D printing aligns closely with lean manufacturing principles by reducing waste, shortening lead times, and improving responsiveness. Manufacturers can produce parts on demand, minimize inventory, and eliminate unnecessary tooling costs.

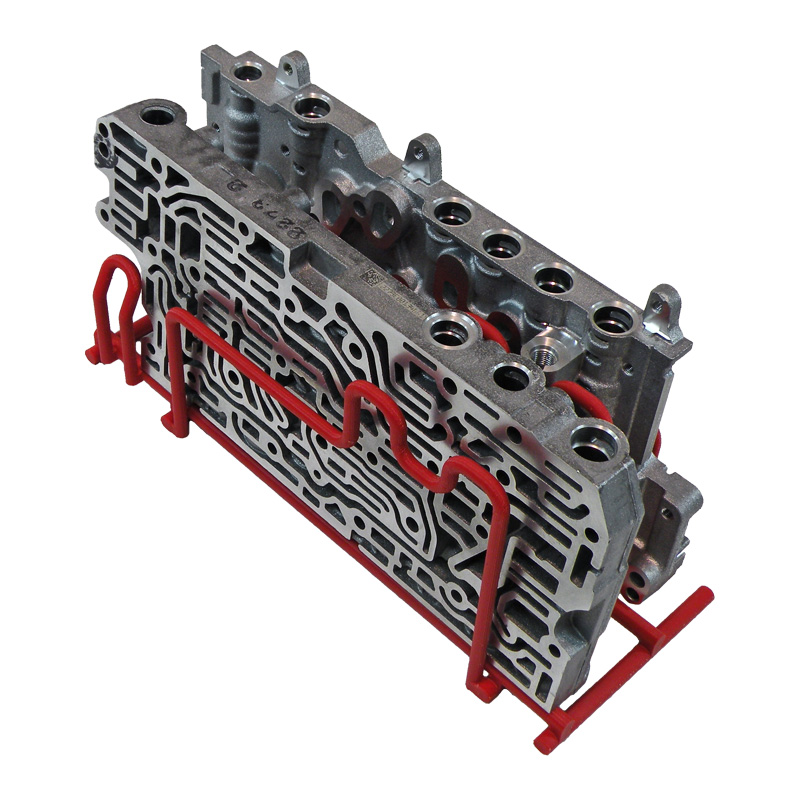

When combined with custom material handling solutions such as wire baskets, carts, and fixtures, additive manufacturing helps streamline workflows and improve overall production efficiency.

3D Printing at Salco Engineering & Manufacturing

Salco Engineering & Manufacturing leverages advanced 3D printing technology to support complex design and prototyping projects across multiple industries. Using materials such as ASA, ULTEM 1010, and Nylon 12, Salco provides accurate, production-ready prototypes that help clients validate designs quickly and confidently.

By integrating 3D printing with in-house engineering, wire forming, and fabrication capabilities, Salco ensures a seamless transition from prototype to full production.

Moving From Concept to Production with Confidence

As 3D printing continues to evolve, its role in manufacturing will only expand. From rapid prototyping and tooling to functional production components, additive manufacturing offers manufacturers a faster, more flexible path to innovation.

If you are looking to reduce development time, improve design accuracy, and bring better products to market, Salco Engineering & Manufacturing can help.

Contact Salco today to learn more about how our 3D printing and prototyping services can support your next manufacturing project.