In the world of manufacturing, the ability to design and create high-quality products is essential. This is where SolidWorks comes in, as it is one of the most popular 3D computer-aided design (CAD) software tools in the industry. SolidWorks has been widely adopted for its ease of use and wide range of features that enable designers to create complex and innovative designs quickly and efficiently.

Benefits of SolidWorks for Manufacturing Design Projects

Design Optimization

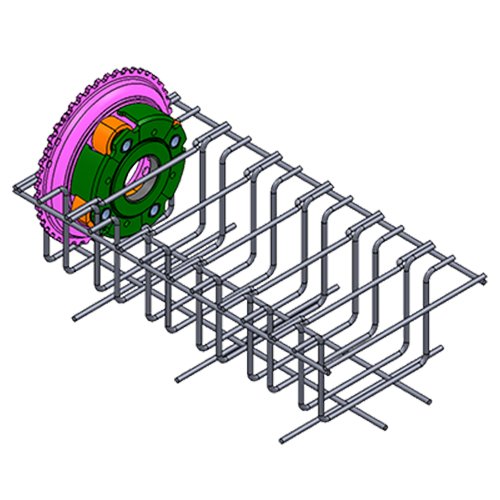

SolidWorks provides designers with the ability to create and test multiple design iterations quickly, allowing them to identify the most effective design for their project. This is particularly important in manufacturing, where small design changes can have a significant impact on the overall quality and performance of a product. Salco Engineering and Manufacturing, for example, uses SolidWorks to design custom industrial carts and steel baskets that can hold automotive parts securely and efficiently.

Collaboration and Communication

One of the most significant advantages of SolidWorks is its ability to facilitate collaboration and communication between designers, engineers, and other stakeholders. By working in a virtual environment, different team members can work on the same design at the same time, sharing ideas and feedback in real-time. Salco Engineering and Manufacturing uses SolidWorks to collaborate with its clients, ensuring that their designs meet their specific needs and requirements.

Cost Savings

SolidWorks enables manufacturers to identify and address potential design flaws early in the design process, avoiding costly errors and rework later on. By identifying and addressing design issues early on, manufacturers can save significant amounts of time and money, reducing the overall cost of the project. Salco Engineering and Manufacturing uses SolidWorks to optimize its designs, minimizing waste and reducing production costs.

Applications of SolidWorks in Manufacturing

One of the most significant advantages of SolidWorks is its ability to facilitate collaboration and communication between designers, engineers, and other stakeholders. By working in a virtual environment, different team members can work on the same design at the same time, sharing ideas and feedback in real-time. Salco Engineering and Manufacturing uses SolidWorks to collaborate with its clients, ensuring that their designs meet their specific needs and requirements.

Cost Savings

SolidWorks enables manufacturers to identify and address potential design flaws early in the design process, avoiding costly errors and rework later on. By identifying and addressing design issues early on, manufacturers can save significant amounts of time and money, reducing the overall cost of the project. Salco Engineering and Manufacturing uses SolidWorks to optimize its designs, minimizing waste and reducing production costs.

Applications of SolidWorks in Manufacturing

SolidWorks has a wide range of applications in manufacturing, including:

Product Design

SolidWorks is widely used in product design, enabling designers to create complex and innovative designs quickly and efficiently. The software provides designers with a range of tools and features that enable them to explore different design options and identify the most effective design for their project.

Industrial Design

SolidWorks is also commonly used in industrial design, allowing designers to create detailed and accurate 3D models of products and components. This is particularly useful in manufacturing, where precision and accuracy are critical.

Weldments

SolidWorks is also commonly used in industrial design, allowing designers to create detailed and accurate 3D models of products and components. This is particularly useful in manufacturing, where precision and accuracy are critical.

Weldments

SolidWorks provides designers with a range of tools and features that enable them to design and create complex welded structures quickly and efficiently. This is particularly useful in manufacturing, where welded structures are widely used in the production of heavy-duty industrial equipment.

Solidworks at Salco

SolidWorks is a powerful tool for manufacturers, enabling them to create high-quality designs quickly and efficiently. Salco Engineering and Manufacturing uses SolidWorks to design custom industrial carts and steel baskets that hold automotive parts securely and efficiently. With the ability to optimize designs, facilitate collaboration, and identify potential cost savings, SolidWorks has become an essential tool for manufacturers looking to streamline their design process and deliver high-quality products to their clients.