As industrial cleaning standards continue to rise and environmentally harmful solvents are phased out, ultrasonic cleaning has emerged as one of the most efficient and eco-friendly alternatives. Manufacturers across automotive, aerospace, medical, and electronics industries now rely on ultrasonic systems to remove debris, oils, fine particulates, and contaminants that traditional cleaning methods often miss.

However, achieving consistent and effective results requires more than just an ultrasonic cleaning system. The ultrasonic cleaning basket, also referred to as an ultrasonic wash basket, plays a crucial role in part stability, solution flow, and cavitation energy transmission. A well-designed stainless steel ultrasonic basket ensures parts are cleaned thoroughly without damage.

This guide explains how ultrasonic cleaning works, why basket design matters, and why stainless steel remains the most reliable material for ultrasonic wash applications.

How Ultrasonic Cleaning Works

Ultrasonic cleaning uses high-frequency sound waves (typically 20–40 kHz) transmitted through a liquid bath. These sound waves create microscopic bubbles in a process called cavitation. When these bubbles collapse, they generate tiny shock waves that lift contaminants from the surface of submerged parts.

This cleaning method is especially effective for components with features that are difficult to clean manually, such as:

- Blind holes

- Fine threads

- Intricate geometries

- Slots, cracks, and recessed areas

Industries that depend on ultrasonic cleaning include automotive, aerospace, dental and medical device manufacturing, electronics, firearms, and precision machining. Many facilities pair ultrasonic cleaning with industrial part wash systems to achieve multi-stage cleaning performance.

The Importance of a Proper Ultrasonic Cleaning Basket

While ultrasonic machines generate the cleaning action, the ultrasonic cleaning basket determines how effectively the energy reaches the parts. A poorly designed basket can dampen ultrasonic waves, restrict fluid flow, or allow parts to collide and sustain damage.

High-quality ultrasonic baskets must allow cavitation energy to pass through freely while maintaining part stability and preventing movement.

Key functions of an ultrasonic cleaning basket include:

- Holding parts securely without restricting cavitation

- Ensuring consistent exposure to ultrasonic waves

- Preventing part-to-part contact and cosmetic damage

- Withstanding prolonged exposure to chemicals and high temperatures

Manufacturers who routinely use ultrasonic cleaners often choose custom-designed ultrasonic wash baskets to match their part size, shape, and cleaning workflow.

What to Look for in an Ultrasonic Cleaning Basket

Not all cleaning baskets are appropriate for ultrasonic use. Low-quality baskets can crack, deform, or even contaminate the cleaning bath. When selecting an ultrasonic cleaning basket, consider the following criteria.

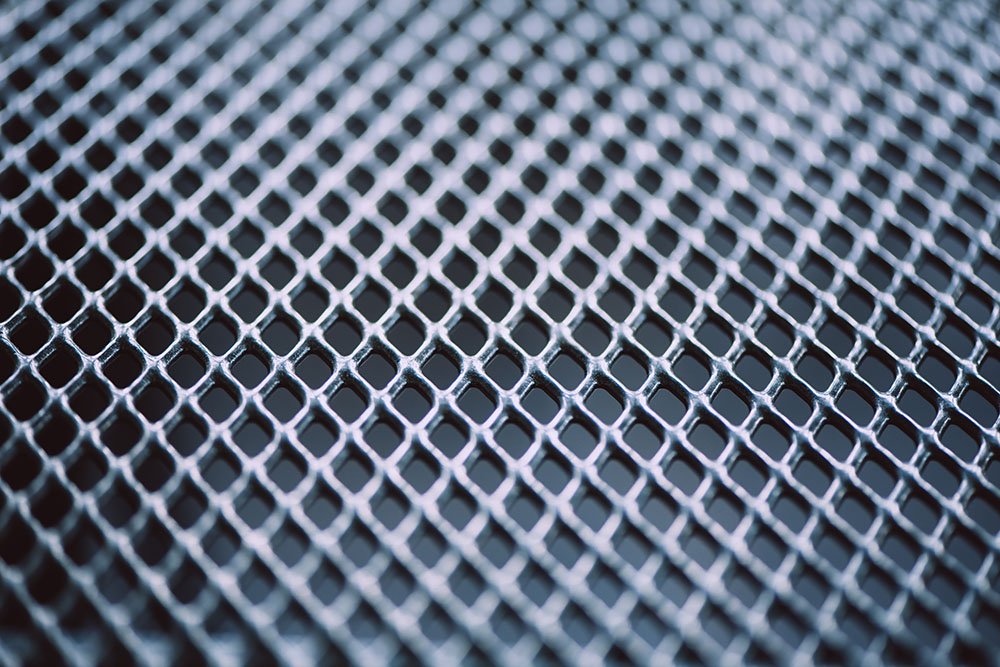

Adequate Open Space and Mesh Structure

The mesh must allow ultrasonic waves and cleaning solutions to pass through freely. Too much material blocks cavitation energy, while too little material compromises strength. Designing the correct mesh size ensures effective cleaning without risking damage to delicate parts.

Secure Part Protection and Positioning

Parts must remain stationary during cleaning. Custom part holders, dividers, or wire forms may be needed to prevent movement, especially for small or delicate components. Many manufacturers lean on custom inserts and dividers to secure complex geometries during ultrasonic cleaning.

Strong Welds and Structural Support

Ultrasonic cleaning involves continuous vibration, which can stress weak welds or inferior materials. High-quality TIG welding and precision fabrication ensure long service life and prevent basket failure.

Chemical and Temperature Compatibility

Ultrasonic cleaning tanks may contain detergents, solvents, or alkaline solutions. Even mild chemicals can damage coated or painted baskets, making material selection crucial.

Why Stainless Steel Is the Best Choice for Ultrasonic Wash Baskets

While coated or painted baskets exist, stainless steel remains the industry standard for ultrasonic cleaning due to its superior performance, safety, and durability.

Advantages of stainless steel ultrasonic wash baskets include:

- Excellent corrosion resistance in chemical cleaning baths

- Smooth, nonporous metal surfaces that resist contamination and buildup

- No risk of coating flaking or peeling, which can interfere with ultrasonic action

- High structural strength for heavy or complex parts

- Compatibility with high temperatures and extended wash cycles

Coated baskets can dampen ultrasonic waves and contaminate tanks as coating materials degrade over time. For this reason, stainless steel mesh is preferred for precision cleaning, especially when paired with automated systems or high-volume production cycles.

Applications Across Industries

Custom stainless steel ultrasonic baskets serve a wide range of applications, including:

- Automotive components such as gears, injectors, and transmission parts

- Medical instruments requiring sterile cleaning processes

- Aerospace hardware with complex geometries

- Electronic circuit boards and small assemblies

- Precision machined parts with tight tolerances

Many facilities integrate ultrasonic cleaning as part of a larger quality-control and contamination-prevention workflow. For example, automotive manufacturers often pair ultrasonic cleaning with technical cleanliness standards to meet strict contamination requirements.

Choosing the Right Ultrasonic Cleaning Basket

To achieve the best results, ultrasonic baskets should be tailored to the specific parts being cleaned. Considerations include:

- Part dimensions and weight

- Required mesh size for fluid flow

- Need for custom fixtures, lids, or dividers

- Chemical exposure and temperature requirements

- Compatibility with automated handling or robotics

Working with an experienced manufacturer ensures consistency, safety, and superior cleaning performance.

Get Custom Stainless Steel Ultrasonic Baskets Designed for Your Process

Salco Engineering specializes in designing and fabricating stainless steel ultrasonic wash baskets that improve cleaning consistency, protect delicate components, and withstand demanding industrial environments. Whether you need a simple mesh basket or a complex multi-level fixture, Salco can engineer a solution tailored to your parts and cleaning process.

Contact Salco Engineering today to request a quote or discuss your ultrasonic cleaning basket requirements. Our team is ready to help you improve cleaning efficiency, reduce part damage, and enhance your quality control processes.