The field of cleaning is always evolving. In the interest of our planet’s ecosystem, vapor degreasing with chlorinated and fluorinated solvents, which has long been the industry norm, is being phased out. At the same time, the amount of cleaning required is always growing.

In this context, ultrasonic cleaning has since gained traction. Ultrasonic cleaning saves time and money, and it is particularly effective in removing dirt and debris from the surface of a produced part compared to manual cleaning.

On the other hand, manufacturers need well-designed ultrasonic parts cleaning baskets to get the greatest results from ultrasonic parts cleaning operations.

Exploring Ultrasonic Cleaning

Ultrasonic cleaning is essentially “cleaning with sound,” a liquid gets sprayed with high-frequency, high-intensity sound waves that are unheard of by humans. The vibrations caused by the sonic waves aid in the dislodging of pollutants from the submerged object.

Metals, glass, rubber, ceramics, and some hard polymers are all acceptable for cleaning with ultrasonic cleaning technology. Ultrasonic cleaning is very effective in eliminating pollutants that have clung to the item’s surface, such as those that have blind holes, fissures, or recesses.

Ultrasonic cleaning systems get used in many industries, including medical devices, aerospace, dental, electronics, jewelry, weapons, and automotive.

Ultrasonic Cleaning Baskets

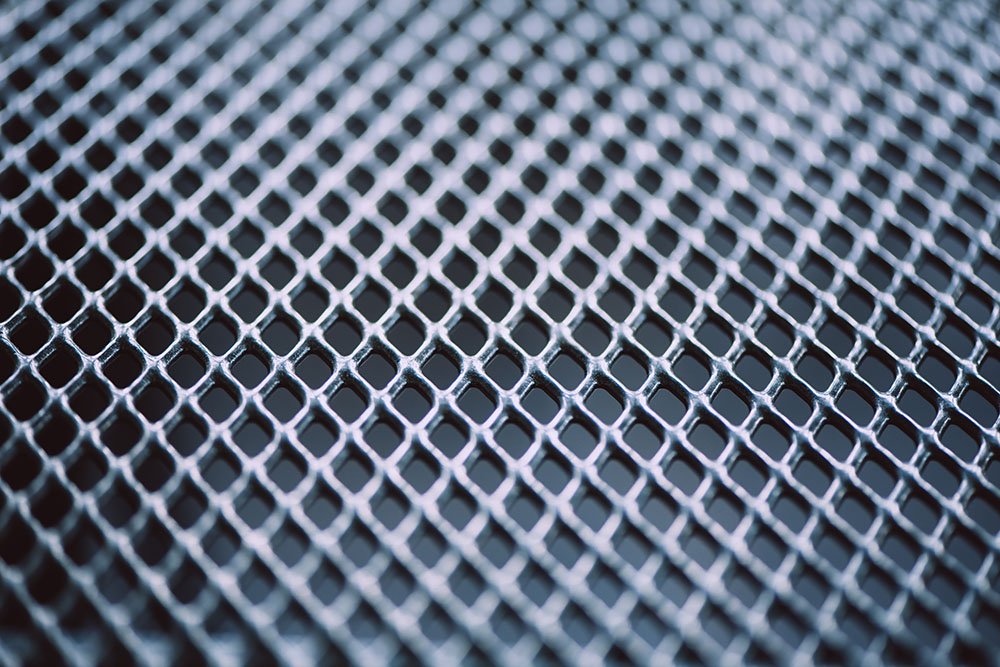

A container is required when using an ultrasonic cleaner to clean parts. These containers or ultrasonic cleaning baskets that hold the pieces through this cleaning procedure, on the other hand, could get damaged. This possibility is because ultrasonic cavitation is a method of removing dirt and debris from the surface of an object by shaking it loose with powerful vibrations and possibly caustic chemicals.

Furthermore, if the design of an ultrasonic cleaning basket is incorrect, it may cause damage to the parts it carries. The problem is that not all ultrasonic cleaning baskets are well-made. Far too many manufacturers wind up buying cheap parts for cleaning baskets only to discover that it contains catastrophic defects that prevent them from cleaning their parts using ultrasonics.

With that, here are important things to look for when choosing an Ultrasonic Cleaning Basket:

- Open space

- Protection for held parts

- Strong Welds and Wires

Additionally, a cleaning basket is usually completely submerged in a fluid bath while using ultrasonic components cleaning. Thus, choosing a stainless steel ultrasonic wash basket is crucial. The specific chemicals in the bath can vary from one ultrasonic part cleaning operation to the next, and even the mildest solutions can be harmful to parts cleaning baskets.

Although alternatives such as coated and painted baskets are available, stainless steel ultrasonic wash baskets remain superior primarily because coatings can reduce the effectiveness of the wash process and can cause part contamination.

Conclusion

Choosing the best cleaning basket for ultrasonic cleaning is critical. Salco’s experienced staff can develop solutions tailored to your needs to ensure you get the perfect product for you!