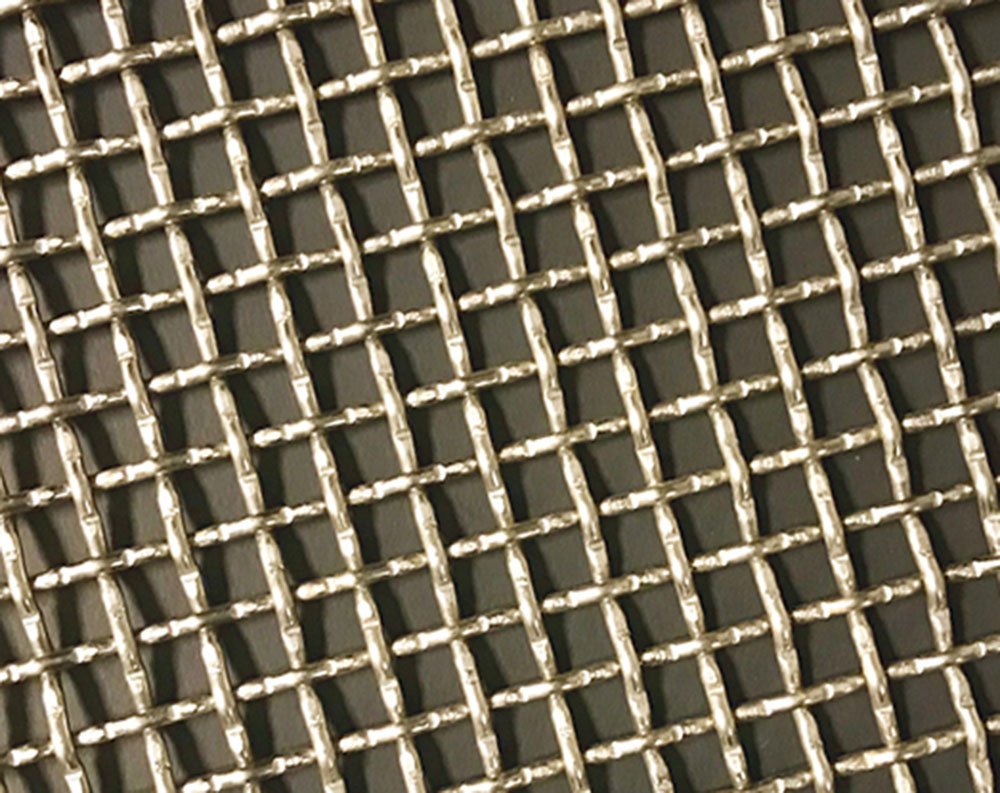

Choosing the right woven wire mesh baskets. Read on to learn more about the advantages of woven wire mesh and their uses in a variety of industries.

The Basket of Choice: Woven Wire Mesh Baskets vs Welded Wire Mesh Baskets

When it comes to choosing a basket for your industrial or commercial needs, there are many options available. Two of the most popular types of baskets are woven mesh baskets and welded wire mesh baskets. In this article, we will discuss the advantages of woven wire mesh baskets, which are the basket of choice for many applications.

Advantages

Mesh baskets are a great choice for a variety of applications because of their unique construction. The wire is woven into a mesh pattern, which creates a sturdy basket that can handle a wide range of materials and weight loads. Some of the advantages include:

- Durability and strength

- Flexibility and versatility

- Good airflow and drainage

- Resistance to corrosion and rust

Applications

Mesh baskets are commonly used in a variety of industries, including automotive, food processing, and medical. Some specific applications include:

- Parts washing and cleaning

- Product drying and curing

- Product storage and handling

- Heat treating and annealing

- Medical instrument sterilization

Conclusion

If you’re in the market for a durable, versatile, and corrosion-resistant basket for your industrial or commercial needs, mesh baskets are a good choise. With their unique construction and many advantages, they are sure to meet your needs and exceed your expectations. Salco Engineering & Manufacturing is a leading provider of high-quality baskets and other custom wire products. With over 60 years of experience in the industry, Salco has built a reputation for excellence in both design and production.

In addition to our extensive manufacturing capabilities, we also offers comprehensive design services to help clients create custom wire products that meet their exact specifications. Our team of experienced engineers and designers work closely with clients to understand their needs and provide tailored solutions to help them achieve their goals.

At Salco, customer satisfaction is a top priority. We offers free quotes to help clients understand the costs associated with their custom wire product needs, and their commitment to quality ensures that each product is manufactured to the highest standards. Contact us today for a quote