In the world of manufacturing, logistics, and warehousing, custom material handling equipment plays a vital role in maintaining efficiency, safety, and productivity. From industrial carts to dunnage inserts and custom wire baskets, these tools are often designed to meet highly specific requirements. A key step in the development of such equipment is prototyping. Prototyping ensures that each product is functional, ergonomic, and durable before moving into full-scale production. Without it, businesses risk inefficiencies, added costs, and potential safety issues.

What is Prototyping in Material Handling Equipment Design?

Prototyping is the process of creating a preliminary version of a product to test its functionality, design, and usability. In the context of custom material handling equipment, it allows engineers and manufacturers to transform conceptual ideas into tangible models that can be analyzed and refined. By leveraging modern tools such as SolidWorks for manufacturing and 3D printing, companies can build accurate prototypes quickly and cost-effectively.

Why Prototyping is Critical in Custom Design

When designing custom solutions, the stakes are high. Each piece of material handling equipment must meet exact specifications for size, load capacity, ergonomics, and durability. Prototyping provides a controlled environment to identify and resolve issues before large-scale manufacturing begins. This reduces risks and ensures that the final product performs as intended under real-world conditions.

Reducing Errors and Costs

Without prototyping, even minor design flaws may go unnoticed until production, leading to costly rework or equipment failure. Prototypes allow these errors to be caught early, reducing waste and lowering long-term costs. For instance, when producing custom stainless steel baskets, prototyping helps verify mesh size, strength, and dimensions before committing to large production runs.

Improving Ergonomics and Worker Safety

Custom equipment often impacts worker interaction, making ergonomics a key factor. Prototyping allows designers to test handle placement, weight distribution, and maneuverability to ensure worker comfort and minimize the risk of injury. This is especially important in the design of ergonomic cart solutions for automotive and industrial facilities.

Faster Product Development Cycles

By testing and refining designs early, prototyping accelerates the overall development cycle. Manufacturers can move from concept to production more efficiently, getting custom solutions into operation faster. For industries like automotive or food production, where timing directly affects profitability, this speed provides a competitive advantage.

Prototyping Methods in Custom Equipment Design

Different prototyping methods are used depending on the type of equipment being developed. Two of the most common methods are:

- 3D Printing Prototypes: Useful for quickly producing models of small components, such as brackets or inserts, for form and fit testing.

- Fabricated Steel Prototypes: Necessary for larger equipment such as pallet carts or sheet pan racks that require real-world strength and load capacity testing.

Applications of Prototyping in Material Handling Equipment

Custom Carts

When designing stainless steel carts or logistics carts, prototypes are used to test mobility, weight distribution, and load handling. Engineers can also evaluate how the carts integrate into existing workflows, ensuring they improve efficiency without disrupting operations.

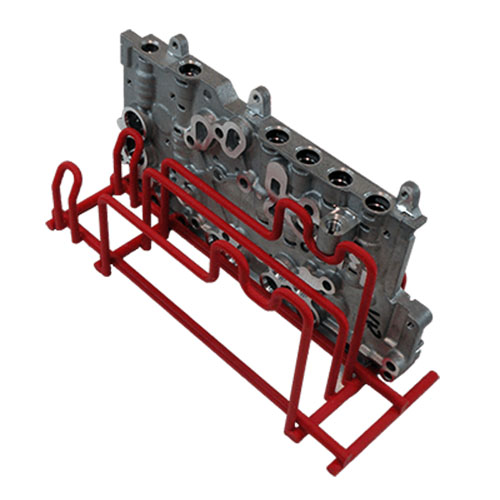

Wire Baskets and Racks

Prototyping is particularly valuable for wire baskets and racks, which often require precision to meet technical cleanliness standards in industries such as automotive and healthcare. Building a prototype allows manufacturers to test wash flow, drainage, and durability before scaling up production.

Dunnage Inserts and Protective Solutions

Custom dunnage is critical for protecting parts during transport. Through prototyping, manufacturers can test fit, cushioning, and stacking efficiency. This ensures parts arrive safely, reducing costs related to damage or rework.

Prototyping for Industry-Specific Needs

Every industry faces unique challenges that influence equipment design. In automotive manufacturing, for example, prototyping ensures that carts for automotive parts can withstand repetitive use while fitting seamlessly into assembly line workflows. In the food industry, prototyping helps confirm that racks and baskets meet hygiene and sanitation requirements. For pharmaceutical applications, prototyping ensures that pharmaceutical baskets meet cleanroom standards while maintaining efficiency.

The Long-Term Benefits of Prototyping

While prototyping may add an initial step to the design process, the long-term benefits far outweigh the upfront investment. Prototypes enhance product reliability, improve ergonomics, reduce costs, and accelerate development timelines. They also foster innovation, as engineers can experiment with new ideas in a low-risk environment before finalizing the design.

Partnering with Salco Engineering for Custom Prototyping

Salco Engineering has decades of experience in custom steel fabrication and material handling equipment design. Our team leverages advanced tools like SolidWorks and 3D printing to create accurate prototypes that validate designs before production. By collaborating closely with clients, we ensure each prototype reflects the specific requirements of the facility, from load capacity to layout compatibility.

Conclusion: Prototyping as a Path to Better Equipment

The role of prototyping in custom material handling equipment design cannot be overstated. It bridges the gap between concept and production, ensuring that each piece of equipment meets performance, safety, and efficiency standards. For manufacturers, logistics companies, and distributors, prototyping is not just an added step—it is a critical part of designing durable, reliable, and cost-effective solutions.

Call to Action

Are you looking to design custom material handling equipment that meets your facility’s unique challenges? Partner with Salco Engineering to take advantage of our expertise in prototyping, design, and manufacturing. Contact us today to learn how our custom solutions can help you achieve greater efficiency, safety, and productivity in your operations.