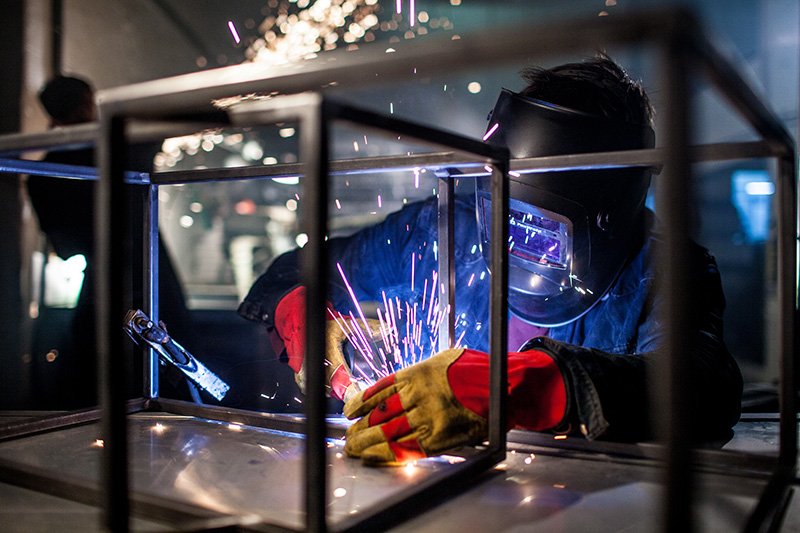

Stainless steel is widely used in industrial applications due to its durability, corrosion resistance, and aesthetic appeal. Welding stainless steel can be a challenging task that requires specialized knowledge and expertise. At Salco Engineering, we are proud to offer MIG and TIG welding services with years of experience in delivering high-quality welded products that meet the unique needs of our clients. In this article, we will discuss the differences between MIG and TIG welding, the benefits of each method, and the expertise that Salco brings to the table.

MIG Welding for Stainless Steel

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular method. MIG welding uses a wire electrode that is continuously fed into the weld pool, creating a strong and consistent weld. The welding process is quick and efficient, making it ideal for high-volume production environments. However, MIG welding is not as precise as TIG welding and may not be suitable for welding thin or delicate materials.

At Salco, we use MIG welding for larger, thicker materials where speed and efficiency are important factors. Our experienced welders are skilled at adjusting the MIG welding settings to create strong, durable welds on stainless steel materials of various thicknesses.

TIG Welding for Stainless Steel

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a more precise welding method that is commonly used for welding stainless steel. TIG welding uses a tungsten electrode to create an electric arc that melts the metal and a separate filler material is used to create the weld. TIG welding produces a clean, precise weld with no spatter, making it ideal for welding thin or delicate materials.

At Salco, we use TIG welding for intricate, precision welding of stainless steel materials such as medical equipment, commercial bakery racks, and automotive components. Our experienced welders are skilled at using TIG welding to create strong, clean welds that meet even the most demanding specifications.

Benefits of MIG and TIG Welding for Stainless Steel

Both MIG and TIG welding offer several benefits. MIG welding is a fast and efficient process that can be used on a wide range of materials and thicknesses. TIG welding produces precise, clean welds that are ideal for thin and delicate materials. Both methods produce strong, durable welds that are resistant to corrosion, making them ideal for industrial applications.

At Salco, we offer both MIG and TIG welding services for stainless steel, allowing us to choose the best method for each project based on the material, thickness, and other factors. Our experienced welders can meet the specific needs of our clients and deliver high-quality welded products that meet their exact specifications.

Salco’s Expertise

At Salco, we have years of experience in welding stainless steel for a wide range of industrial applications. Our experienced welders are skilled at using both MIG and TIG welding methods to create strong, precise welds that meet even the most demanding specifications. We have worked with clients in various industries, including medical, food processing, aerospace, and automotive, and we have delivered custom welded products that meet their unique needs.

We understand that welding requires specialized knowledge and expertise, and we are committed to providing our clients with the highest quality welding services available. Request a quote today for your next project.