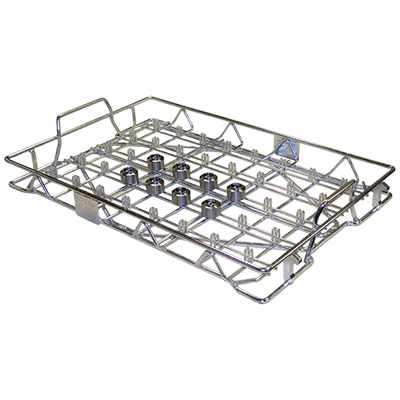

Wire baskets for automotive parts washing. One of the key components of automotive parts washing is wire baskets, which are used to hold parts during the cleaning process and to prevent damage to delicate components. With so many options available in the market, it can be challenging to choose the right wire basket for your specific needs. This guide will provide you with all the essential information you need to know when selecting wire baskets for automotive parts washing.

Types of Wire Baskets for Automotive Parts Washing

There are several types of wire baskets available in the market parts washing. These include stainless steel, mild steel, and specialty alloys. Stainless steel wire baskets are the most common type due to their durability and corrosion resistance. Mild steel wire baskets are an affordable alternative but are less resistant to corrosion. Specialty alloys are used for specific applications where high-temperature resistance or chemical resistance is required.

Factors to Consider

When selecting wire baskets parts washing, several factors need to be considered. These include size, shape, weight capacity, and chemical resistance. The size and shape of the basket should be suitable for the parts being cleaned. The weight capacity of the basket should be sufficient to hold the parts without causing damage. Chemical resistance is also an essential consideration since automotive parts washing involves exposure to harsh chemicals.

Benefits

Wire baskets offer several benefits when used in automotive parts washing. They provide a secure holding place for parts during the washing process, preventing damage to delicate components. Wire baskets can also be customized to fit specific parts, increasing efficiency and reducing the need for multiple baskets. Additionally, wire baskets can be reused multiple times, reducing waste and saving costs.

Advantages

Steel wire baskets are a popular option parts washing due to their numerous advantages. Automotive parts baskets are durable, highly resistant to corrosion, customizable, and cost-effective. Steel wire baskets can withstand exposure to harsh chemicals and temperatures without losing their structural integrity. Customization options allow steel wire baskets to accommodate various part shapes and sizes, increasing efficiency. Steel wire baskets are also cost-effective since they can be reused multiple times without the need for replacement.

Maintenance of Wire Baskets for Automotive Parts Washing

To ensure the longevity and performance of wire baskets, proper maintenance and care are necessary. Wire baskets should be cleaned after each use to remove any residue or debris that may be present. Regular inspections should also be performed to check for any signs of wear and tear. If any damage is detected, the basket should be repaired or replaced as necessary.

Conclusion

Wire baskets are an essential component of automotive parts washing. Choosing the right wire basket for your specific needs can improve the efficiency and effectiveness of your parts washing process. By considering factors such as size, shape, weight capacity, and chemical resistance, you can select the best wire basket for your needs. Steel wire baskets offer numerous advantages over other materials, making them a popular choice in the industry. Proper maintenance and care of wire baskets can ensure their longevity and performance, providing you with a reliable solution for your automotive parts washing needs.