CNC Milling

Precision CNC Milling for Diverse Industries

At Salco Engineering & Manufacturing, our CNC milling services combine advanced technology with decades of fabrication expertise to deliver precision components for a variety of industries. From automotive and aerospace to medical and electronics manufacturing, our team produces complex parts with tight tolerances and exceptional surface finishes.

Our precision milling capabilities allow us to create parts that meet the highest performance and quality standards. Whether you need a single prototype or high-volume production, Salco’s CNC machining team provides reliable, repeatable results that ensure efficiency, consistency, and cost-effectiveness throughout your entire project lifecycle.

Advanced CNC Milling Technology

Our state-of-the-art facility is equipped with modern CNC milling machines capable of machining a wide range of materials, including aluminum, stainless steel, titanium, and industrial plastics. We use advanced CAD/CAM software to transform digital models into precise, machined components. This technology allows us to achieve exceptional accuracy in both simple and complex geometries—ideal for demanding industries where precision and consistency are essential.

Our equipment lineup includes multi-axis machines that support intricate milling operations and high-speed cutting. Combined with our expertise in stainless steel fabrication and wire forming, our CNC milling capabilities form a complete manufacturing solution for clients seeking tight-tolerance components that integrate seamlessly with other fabricated parts.

Comprehensive and Custom Milling Solutions

Every project at Salco begins with a clear understanding of our client’s design goals and performance requirements. We provide end-to-end support, from concept and prototyping to final production and quality assurance. Whether you are refining an existing design or developing a completely new part, our engineering team can assist with CAD modeling, material selection, and manufacturability analysis.

By leveraging our in-house engineering and design and prototyping capabilities, we help clients minimize production risks and optimize performance. Prototypes can be tested for fit, function, and durability before final manufacturing begins, reducing lead times and ensuring each part performs exactly as intended.

Our custom CNC milling services are ideal for:

- Automotive component production and tooling

- Aerospace brackets, housings, and precision fixtures

- Medical and laboratory equipment parts

- Industrial enclosures and machine components

- Custom fixtures for robotics and automation systems

Integration with Fabrication and Assembly

Salco’s CNC milling services integrate directly with our broader fabrication and assembly capabilities, including custom steel fabrication and complete metal fabrication and finishing. This allows us to handle both the precision machining and the large-scale structural fabrication aspects of a project in-house—streamlining timelines and maintaining full control over quality.

By keeping every step of production under one roof, we reduce vendor dependencies and improve turnaround times. Whether you need CNC-milled components integrated into wire assemblies, steel frames, or modular cart systems, Salco provides cohesive solutions designed for performance and durability.

Commitment to Quality and Precision

Quality assurance is a key part of our CNC milling process. Each component undergoes dimensional inspection and surface-finish verification to ensure that all specifications are met. Our team adheres to strict manufacturing standards and uses calibrated inspection tools to confirm the precision and consistency of every machined part.

We continuously invest in process improvements and equipment upgrades to maintain our reputation for precision and reliability. This commitment to excellence enables us to deliver parts that not only meet, but often exceed, customer expectations.

Why Choose Salco for CNC Milling

When you choose Salco Engineering & Manufacturing, you’re partnering with a company that values precision, performance, and partnership. Our in-house CNC milling services are supported by a highly skilled team of machinists, engineers, and quality specialists who bring practical experience and problem-solving expertise to every project.

Clients across North America rely on Salco for their machining and fabrication needs because we offer:

- High-tolerance milling for complex or custom geometries

- Scalable production from prototype to volume manufacturing

- Comprehensive design support and manufacturability analysis

- Responsive lead times and dedicated customer service

Industries We Serve

Our CNC milling capabilities support manufacturers across many sectors. We regularly work with clients in automotive, aerospace, food production, medical, and heavy equipment manufacturing—industries that demand precision and reliability in every part.

To learn more about how Salco supports each of these industries, visit our Industries page for an overview of our specialized material handling and fabrication solutions.

Partner with Salco Engineering & Manufacturing

Whether you’re developing a new component or improving an existing design, Salco’s CNC milling team can help you achieve the precision, efficiency, and quality your operation requires. From initial prototype to full production, our commitment to accuracy and innovation ensures that every project is built to perform.

Contact Salco Engineering & Manufacturing today to request a quote or discuss your next CNC milling project. Our team is ready to help you create high-performance components that support your production goals and manufacturing efficiency.

Ready for a Quote?

Salco can quote projects of all shapes and sizes. If you have questions about our services, please click here to contact us. Someone from our team will be happy to assist you.

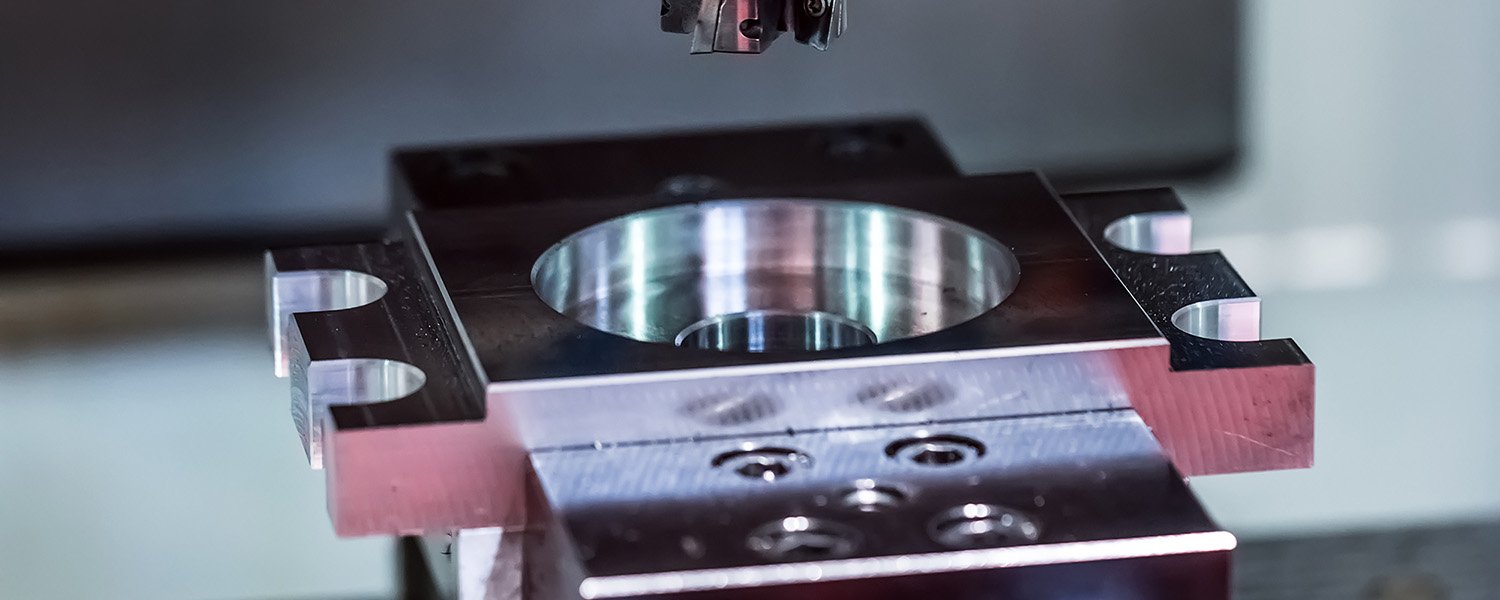

Salco offers custom milling services using our Fryer MB-16R. Request a quote today. The Fryer MB-16R milling machine is a versatile and reliable machine designed to meet the needs of modern machining applications. It offers a wide range of features and capabilities that make it suitable for use in various industries, including aerospace, automotive, and medical.

Salco offers custom milling services using our Fryer MB-16R. Request a quote today. The Fryer MB-16R milling machine is a versatile and reliable machine designed to meet the needs of modern machining applications. It offers a wide range of features and capabilities that make it suitable for use in various industries, including aerospace, automotive, and medical.

The Fryer MB-16R milling machine features a powerful spindle motor that delivers high torque and speed. This makes it suitable for machining a wide range of materials, including steel, aluminum, and titanium. It also has a high-speed tool changer, which allows for rapid tool changes, saving time and increasing productivity.

In addition to its excellent construction and powerful spindle motor, the Fryer features the latest generation Siemens 828D CNC control, which offers advanced features such as conversational programming and high-speed machining. This makes it easy for operators to set up and operate the machine, resulting in increased productivity and efficiency.

The Fryer MB-16R milling machine is a reliable, high-performance machine that is suitable for a wide range of machining applications. Its rigid construction, powerful spindle motor, and user-friendly control system make it a popular choice for industries such as aerospace, automotive, and medical. If you are looking for high-quality milling services, get in touch with Salco for a quote.

Machine Capacity

- X Travel – 60″

- Y Travel – 25″

- Z Travel – 24″

- Table Load – 2950 lbs

- Ballscrew Size – 1.57″

- Table Size – 18″ x 70″

- T-Slots (No. / Width) – 5 / 0.630″

- Table Top to Floor – 36″

Spindle

- Motor (Peak) – 12 HP

- Max Spindle Torque – 40 ft/lbs

- Spindle Speeds – 60 – 80000 RPM

- Tool Type / Taper – CAT 40 (BT-40 Optional)

- Spindle Nose to Table (Max – Min) – 28″ – 4″

- Spindle Center to Column – 25″

ATC

- Tool Storage Capacity – 12 (20 optional)

- Tool Change Time – 7 seconds

- Tool Selection – Bi-Directional

- Max Adjacent Tool Diameter – 5.5″

- Max Tool Weight – 15.4 lbs

- Max Tool Length – 11.8″

Performance

- Positioning Accuracy – +/- 0.0002″

- Positioning Repeatability – +/- 0.001″

- Rapid Traverse – 400 IPM

- Cutting Feed Rate – 0.001 – 300 IPM

- Axis Thrust (Peak) – 4400 lbs