In automotive manufacturing and remanufacturing, the quality of parts cleaning directly impacts downstream processes such as coating, assembly, and inspection. Wire baskets play a central role in this process by securely holding components during ultrasonic washing, spray washing, or immersion cleaning cycles. Choosing the right automotive parts washing basket ensures consistent cleanliness, prevents component damage, and increases process efficiency.

This guide explores the key features, types, and advantages of wire baskets used in automotive parts washing, along with expert considerations to help you select the right solution for your facility.

Why Wire Baskets Matter in Automotive Parts Cleaning

Automotive parts washing requires equipment that supports repeatable, high-quality cleaning results. Wire baskets provide the structural support, airflow, and drainage needed for cleaning fluids to circulate around the part. The right cleaning basket can reduce contamination risks, prevent part-on-part damage, and withstand the demanding conditions of industrial wash systems.

These baskets are especially critical when used with advanced cleaning methods such as ultrasonic washing or spray wash systems, which rely on unobstructed fluid flow and proper part spacing to achieve reliable cleanliness.

Common Types of Wire Baskets for Automotive Parts Washing

Wire baskets for automotive cleaning systems are available in several materials and configurations, each suited to a specific environment or part type.

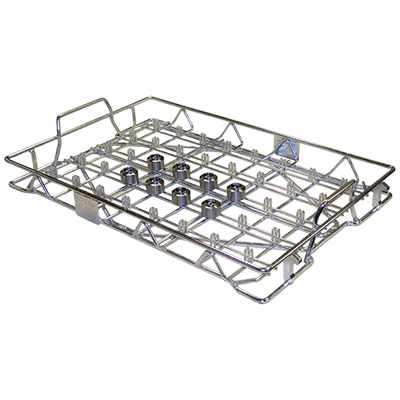

Stainless Steel Wire Baskets

Stainless steel wire baskets are the most widely used solution for automotive parts washing due to their durability, corrosion resistance, and compatibility with harsh cleaning agents. They are ideal for high-temperature wash cycles and demanding cleaning applications. Many automotive manufacturers rely on stainless steel baskets for both general washing and specialized processes such as precision component cleaning.

Mild Steel Wire Baskets

Mild steel baskets offer a more economical option, though they are less resistant to corrosion. They are suitable for non-corrosive wash environments or applications where baskets are used for short-term or single-process workflows.

Special Alloy or Coated Wire Baskets

Specialty alloys and coatings are used when applications require enhanced chemical resistance, high-temperature stability, or specific surface finishes. For example, some facilities integrate coated baskets alongside other protective solutions such as nylon-coated baskets for applications that demand extra abrasion resistance.

Key Considerations When Selecting a Wire Basket for Parts Washing

Every automotive cleaning process is different, so selecting the right basket design is essential.

Basket Size and Shape

The dimensions of your cleaning basket must be compatible with both the wash system and the parts being processed. Proper fit prevents unnecessary movement and reduces the risk of part damage. Many facilities also integrate custom inserts for improved protection during washing.

Weight Capacity and Structural Strength

Automotive parts vary significantly in weight. A basket must support the load without bending, sagging, or compromising part alignment. Reinforced bottom grids and heavy-gauge wire frames help ensure long-term durability.

Chemical and Temperature Resistance

Parts washing often involves detergents, degreasers, and high-temperature cleaning cycles. Choosing materials with strong corrosion resistance protects both the basket and the parts it holds.

Mesh Size and Openings

The mesh pattern affects fluid flow, drainage, and the security of parts during washing. Smaller openings protect small components, while larger mesh designs maximize agitation and cleaning efficiency.

Advantages of Steel Wire Baskets for Automotive Cleaning

Wire baskets remain the industry standard for automotive parts washing because they offer a unique combination of strength, efficiency, and longevity.

Superior Durability

Steel wire baskets withstand rigorous wash cycles, industrial chemicals, and daily use without breaking down. Many automotive manufacturers complement their wash systems with durable welded stainless-steel assemblies to improve long-term reliability.

Custom Fit for Any Part

Customization reduces the need for multiple baskets and improves cleaning consistency. Engine components, gears, EV parts, and precision assemblies can all be supported with part-specific basket designs.

Improved Cleaning Performance

Wire baskets allow cleaning fluids and ultrasonic waves to reach every surface of the part. This maximizes cleaning efficiency and supports technical cleanliness standards required in automotive production.

Cost-Effective and Reusable

High-quality wire baskets can be reused for years, reducing long-term costs. Their reusability also supports sustainability goals within automotive manufacturing.

Maintaining Your Automotive Parts Washing Baskets

Proper maintenance extends basket life and maintains cleaning performance.

Post-Wash Cleaning

Clean baskets after each cycle to remove chemical residue or debris. This prevents buildup that can interfere with cleaning processes.

Routine Inspections

Look for broken welds, bent wires, or signs of corrosion. Even minor issues can compromise basket integrity and part protection.

Timely Repairs or Replacement

Damaged baskets should be repaired or replaced immediately to avoid part contamination or cleaning equipment issues.

Choosing the Right Basket

Choosing the right wire basket for automotive parts washing enhances cleaning performance, improves part protection, and supports efficient manufacturing processes. By evaluating factors such as material, durability, mesh size, and chemical compatibility, manufacturers can select baskets that deliver long-term reliability and superior cleaning results.

If your facility needs high-quality cleaning solutions such as stainless steel ultrasonic baskets, mesh washing containers, or custom-designed automotive parts baskets, Salco Engineering can help. We specialize in durable, precision-engineered wire products designed for industrial cleaning systems.

Contact Salco Engineering today to request a quote or discuss a custom wire basket designed for your automotive parts washing application.