Material Handling for the Automotive Industry

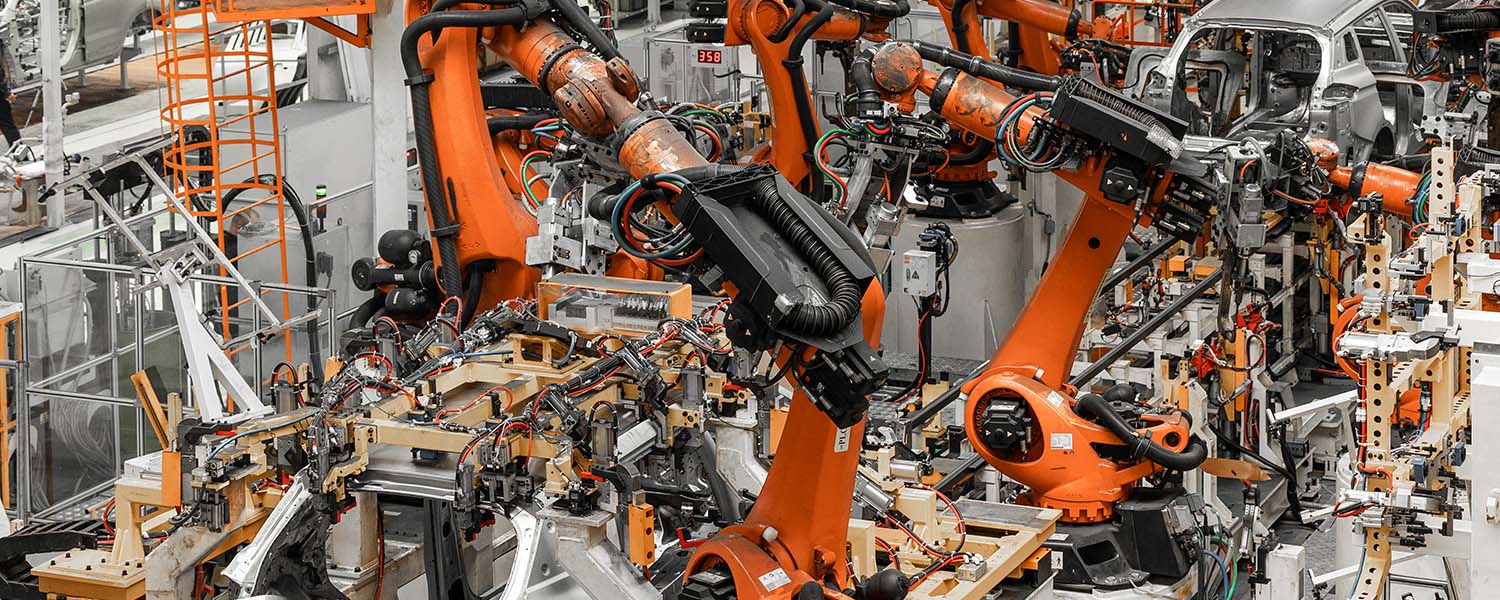

Custom Material Handling Solutions for Automotive Manufacturing

Automotive manufacturers require efficient, durable, and precise material handling systems to keep production lines running smoothly. At Salco Engineering & Manufacturing, we specialize in designing and fabricating custom carts and trolleys, wire baskets, racks, and dunnage systems specifically for the automotive industry. Our products are engineered to withstand the demands of high-volume automotive assembly environments while supporting lean manufacturing principles.

Why Material Handling Matters in Automotive Manufacturing

Automotive production involves thousands of components moving through multiple stages of assembly, finishing, and quality inspection. The way these parts are stored, transported, and staged has a direct impact on efficiency, quality control, and worker safety. Without properly designed material handling solutions, manufacturers risk increased downtime, part damage, contamination, and workflow inefficiencies.

Salco provides solutions that optimize:

- Work-in-process (WIP) part handling for engines, transmissions, and assemblies

- Ergonomic transport to reduce worker fatigue and injury

- Contamination control through clean and corrosion-resistant designs

- Space utilization in production areas and warehouses

Tailored Solutions for the Automotive Industry

Every automotive facility has unique challenges, from specialized part geometries to space constraints and automated handling requirements. Salco designs custom industrial carts, trolleys, and baskets to meet these needs, ensuring seamless integration with your assembly lines, wash systems, and robotic automation cells. Our capabilities include:

- Custom wire baskets for part washing and robotic loading

- Stainless steel carts for heavy-duty and cleanroom applications

- Fluid-draining carts for engines, gearboxes, and hydraulic components

- Dunnage systems and wire inserts for secure part transport

Expertise in Automotive Manufacturing Applications

Salco Engineering has decades of experience working with OEMs and Tier 1 suppliers. Our understanding of automotive manufacturing challenges allows us to provide solutions that enhance productivity and meet technical cleanliness standards. Common automotive applications include:

- Powertrain and drivetrain part handling

- Engine and transmission assembly

- Steering and suspension component staging

- Paint shop and finishing line carts

- Parts washing baskets for high-volume cleaning systems

Our products are designed to perform under high-volume conditions, reducing handling times and minimizing the risk of part damage during transport and processing.

Precision Engineering for Automotive Manufacturing

In automotive manufacturing, precision and repeatability are critical. Salco utilizes advanced design software, 3D modeling, and laser cutting technology to deliver products that meet exact specifications. Our engineering process ensures:

- Compatibility with automated handling systems and robotic arms

- Structural integrity for heavy or oversized parts

- Ergonomic designs for safe manual handling

- Compliance with industry standards for cleanliness and quality

We also offer design and prototyping services to validate performance before full-scale production, reducing the risk of costly adjustments during implementation.

Key Automotive Material Handling Solutions from Salco

Custom Automotive Carts

Our carts are built for heavy-duty use and can include features like rotating platforms, adjustable shelving, fluid drainage systems, and tow bars for AGVs or tugger trains.

Wire and Stainless Steel Baskets

Designed for part washing, robotic handling, and storage, our baskets can be fabricated from stainless steel or coated wire for added corrosion resistance. Options include wire dividers, nesting inserts, and ergonomic handles.

Dunnage Inserts

Custom wire inserts for plastic totes provide cost-effective part protection during transport and staging. These inserts are lightweight, durable, and reusable for returnable packaging programs. Learn more about custom dunnage inserts.

Fluid Drainage Carts

Essential for powertrain assembly and service areas, these carts feature sloped drip trays with drainage systems leading to removable collection containers, reducing contamination and cleanup time.

Quality Assurance for Automotive Solutions

Salco maintains strict quality control throughout design and manufacturing. Every product undergoes rigorous inspection to ensure structural integrity, load capacity, and compliance with customer specifications. Our commitment to quality ensures long-term durability and reliable performance in demanding production environments.

Collaborative Partnership for Automotive Manufacturers

We believe that the best solutions are created through collaboration. Our team works closely with clients from concept to delivery, providing engineering support, design validation, and responsive service. By understanding your workflow and operational goals, we develop solutions that reduce downtime, improve safety, and maximize throughput.

Contact Salco for Custom Automotive Solutions

Salco Engineering & Manufacturing is your trusted partner for automotive material handling equipment that delivers performance, precision, and durability. Whether you need custom carts, wash baskets, or complete part handling systems, our team can design and build a solution that fits your exact needs.

Request a Quote Now or Contact us today to learn more about how we can help optimize your automotive manufacturing operations.