What Are Returnable Plastic Dunnage Systems?

Returnable plastic dunnage refers to reusable containers—typically plastic totes or bins—used to transport and store components across industries such as automotive, aerospace, medical device manufacturing, and electronics. These containers are lightweight, stackable, and designed for long-term use.

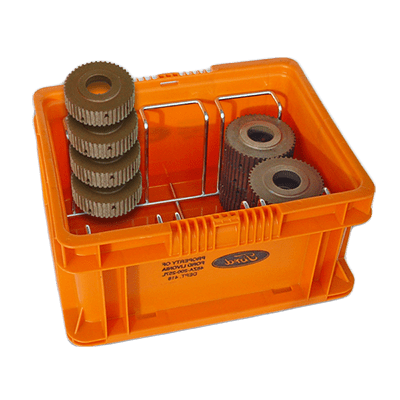

Salco Engineering enhances these systems by adding custom steel wire dividers or precision-fitted inserts inside the totes. This approach keeps each part securely separated, eliminating contact damage and reducing shipping waste compared to single-use packaging. Returnable systems also improve sustainability and reduce costs by replacing disposable packaging with durable, reusable containers that maintain integrity over time.

Advantages of Custom Dunnage Inserts

Custom dunnage inserts are an essential component in any modern material handling and logistics system. By tailoring the insert to the exact shape and size of your parts, Salco helps manufacturers protect their inventory while improving workflow efficiency.

Enhanced Part Protection

Our custom inserts provide a precise fit for each component, holding parts securely in place to prevent abrasion, collision, or shifting during transport. This level of precision is particularly valuable in industries like automotive and aerospace, where part geometry and surface finish integrity are critical.

Improved Efficiency and Handling

Custom dunnage inserts help streamline production and logistics by allowing for faster loading, unloading, and transport. The consistent layout also enables automation and robotic handling—reducing manual labor and minimizing cycle times.

Better Organization and Traceability

A well-designed insert keeps every part in its proper position, improving visibility and reducing the risk of loss or mix-ups. Dunnage systems can be labeled or color-coded for part identification, simplifying inventory tracking and workflow organization throughout your facility.

To see how dunnage fits into larger operational systems, explore our article on in-process material handling solutions and how they improve manufacturing efficiency.

Custom Design and Engineering Capabilities

Every Salco dunnage insert project begins with a collaborative design process. Our engineering team works closely with clients to understand specific part geometries, handling requirements, and production environments. Using SolidWorks CAD software and precision measurement tools, we develop 3D models and prototypes that simulate real-world use and identify potential improvements before production.

For more insight into our approach, visit our page on design and prototyping to learn how Salco’s engineers ensure quality and accuracy from concept through fabrication.

Wire Inserts for Plastic Totes

Our most common solution involves custom steel wire inserts designed to fit securely into standard returnable plastic totes. These lightweight wire frames offer excellent strength while keeping container weight low. The result is a modular, returnable, and easily stackable system that protects valuable components without adding unnecessary bulk.

Each wire insert is custom-formed and welded in-house using advanced CNC wire bending and precision welding processes, ensuring structural consistency and repeatable accuracy.

Materials and Construction Options

Salco offers a wide selection of materials and finishes for dunnage inserts depending on your industry, part type, and environment.

- Wire inserts made from mild or stainless steel for strength and longevity

- Plastic, foam, or polymer dividers for lightweight part protection

- Powder-coated finishes for corrosion resistance and visual identification

- Electropolished or zinc-plated options for cleanroom or corrosive environments

We can also integrate hybrid dunnage designs that combine wire inserts with custom trays or padding for maximum flexibility and impact resistance.

To learn more about how surface treatments improve product lifespan, see our article on zinc plating for steel products.

Industries That Benefit from Custom Dunnage Inserts

Our custom dunnage products are used by manufacturers in a wide variety of industries, including:

- Automotive part and component production

- Aerospace assembly and testing facilities

- Medical device and laboratory equipment manufacturing

- Electronics and semiconductor production

- Industrial and heavy machinery assembly

Each of these industries depends on reliable material handling systems to maintain production speed, safety, and precision—and Salco’s dunnage solutions are built to support those same objectives.

Why Choose Salco for Custom Dunnage Inserts

With over 60 years of experience in manufacturing custom material handling products, Salco Engineering & Manufacturing has the expertise, technology, and craftsmanship to deliver reliable dunnage systems that meet the most demanding specifications.

We maintain full in-house control of the process—from design and wire forming to assembly and quality inspection—ensuring that every insert meets exact tolerances and performance expectations. Our commitment to precision and durability makes Salco a trusted partner for manufacturers seeking long-term value in their dunnage and material handling systems.

Request a Custom Dunnage Quote

Protecting your parts starts with a well-designed dunnage system. Salco Engineering & Manufacturing creates custom inserts that improve organization, reduce waste, and protect your products during every stage of handling.

Request a quote today to speak with our engineering team about your next dunnage insert project. We’ll help design a custom solution that enhances part protection, reduces costs, and integrates seamlessly into your material handling process.