Stainless steel baskets have become indispensable in various industrial applications, offering a combination of durability, corrosion resistance, and versatility. In this blog post, we explore the wide-ranging industrial uses of stainless steel baskets, highlighting their key benefits and why they are a preferred choice across different sectors.

Stainless Steel Baskets in Industrial Settings

Stainless steel baskets find extensive use in industrial environments due to their adaptability to diverse applications. Let’s delve into some prominent industrial uses:

Parts Cleaning and Degreasing

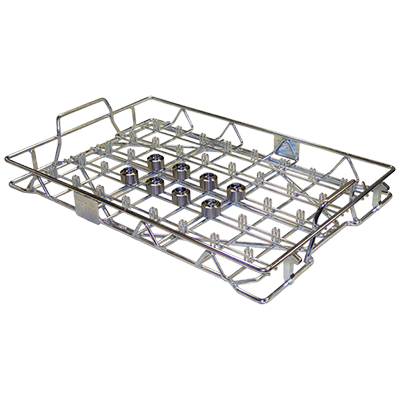

Stainless steel baskets excel in parts cleaning and degreasing processes. The robust construction of these baskets allows them to withstand the harsh chemicals and high temperatures often associated with industrial cleaning. Their open mesh design facilitates effective cleaning, ensuring thorough removal of contaminants from various components.

Heat Treatment Processes

Industries involved in heat treatment processes rely on stainless steel baskets to hold and transport components through extreme temperature variations. The heat-resistant properties of stainless steel make these baskets ideal for applications such as annealing, hardening, and tempering.

The Advantages of Stainless Steel in Industrial Environments

Stainless steel’s inherent characteristics make it a material of choice for industrial baskets. Let’s explore the advantages that contribute to its widespread use:

Corrosion Resistance

Industrial environments often expose equipment to corrosive substances. Stainless steel’s resistance to corrosion ensures that baskets remain structurally sound over time, even when exposed to harsh chemicals or extreme weather conditions.

Durability

Stainless steel baskets are renowned for their durability. In demanding industrial settings, where wear and tear are inevitable, the longevity of these baskets becomes a valuable asset. They withstand heavy loads, impacts, and repetitive use without compromising performance.

Hygienic Properties

In industries where cleanliness is paramount, such as pharmaceuticals and food processing, stainless steel baskets meet strict hygiene standards. The smooth, non-porous surface of stainless steel is easy to clean and sanitize, preventing the accumulation of bacteria and contaminants.

Custom Solutions for Industrial Challenges

Recognizing the diverse needs of industries, manufacturers like Salco Engineering offer custom solutions for stainless steel baskets. Tailoring the design and specifications of baskets ensures they meet the unique requirements of each industrial application.

Aerospace Component Handling

In the aerospace industry, precision and care in handling components are critical. Custom stainless steel baskets provide the necessary support for delicate aerospace parts, ensuring they remain in pristine condition throughout the manufacturing process.

Automotive Manufacturing

Automotive manufacturing demands precision and efficiency. Stainless steel baskets are integral to processes such as parts washing, heat treatment, and transportation of components, contributing to the seamless production of high-quality automotive parts.

Conclusion

Stainless steel baskets play a vital role in enhancing efficiency, cleanliness, and durability across a spectrum of industrial applications. From parts cleaning and heat treatment to aerospace and automotive manufacturing, their versatility makes them a go-to solution for numerous challenges in industrial settings.

As industries continue to evolve, the demand for reliable and customized solutions remains high. Stainless steel baskets, with their unmatched attributes, are sure to remain a cornerstone in the ever-changing landscape of industrial processes.