Selecting the right industrial basket has a direct impact on product protection, process efficiency, and long-term equipment performance. Whether baskets are used for parts washing, heat treating, storage, or material handling, the construction method plays a major role in how well they perform. Two of the most common options are woven wire mesh baskets and welded wire mesh baskets. While both serve important roles, woven mesh baskets are often the preferred solution for demanding industrial applications.

This guide compares woven wire mesh baskets and welded wire mesh baskets, explains their differences, and outlines why woven mesh baskets are frequently chosen for high-performance environments.

Understanding Woven Wire Mesh and Welded Wire Mesh Baskets

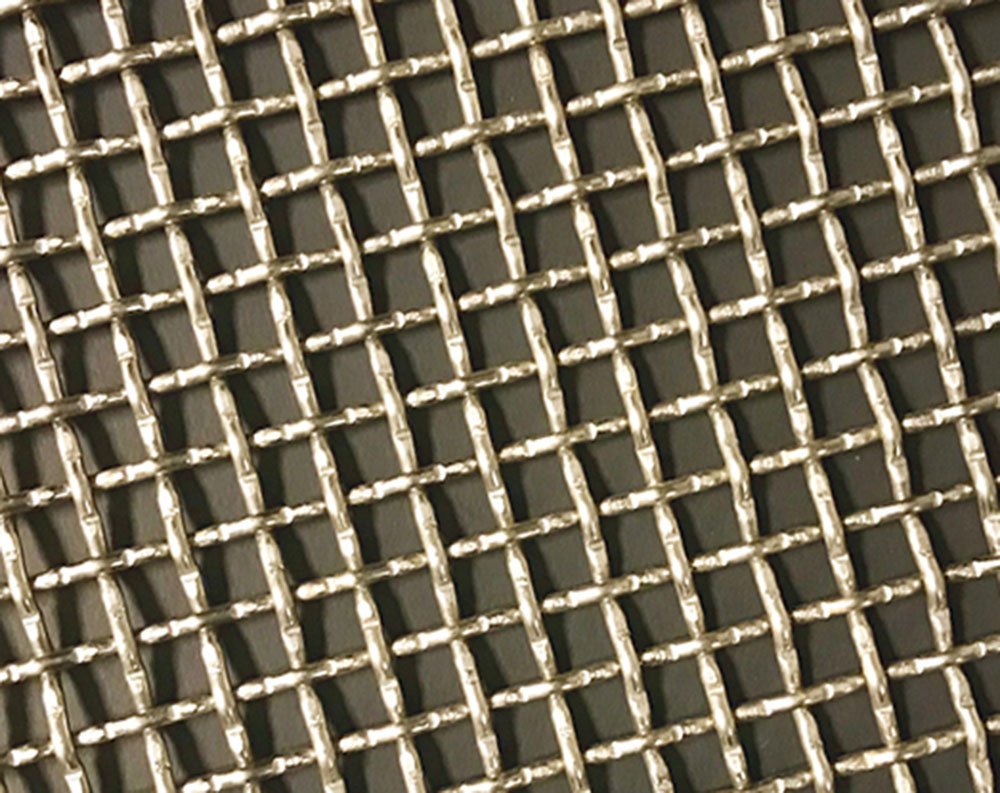

Woven wire mesh baskets are manufactured by interlacing individual wires over and under one another, similar to fabric weaving. This construction creates a flexible yet strong mesh structure that distributes loads evenly across the basket. Welded wire mesh baskets, on the other hand, are produced by welding intersecting wires together at fixed points, resulting in a rigid grid-like structure.

Both designs have advantages, but the woven construction provides unique performance benefits that make it well suited for harsh, high-temperature, and precision-driven processes.

Key Advantages of Woven Wire Mesh Baskets

Strength with Flexibility

Woven mesh baskets offer excellent load distribution because the woven structure allows the basket to flex slightly under weight rather than concentrating stress at weld points. This flexibility helps reduce cracking, deformation, and premature failure, especially in high-heat or high-load environments.

Superior Airflow and Drainage

The consistent openings created by woven mesh allow for unrestricted airflow and fluid movement. This makes woven mesh baskets ideal for applications such as parts washing, drying, curing, and heat treating, where proper circulation is essential for consistent results. Many manufacturers rely on woven designs for ultrasonic cleaning processes and other precision cleaning operations.

Reduced Risk of Part Damage

Because woven mesh baskets do not rely on rigid welded intersections, they tend to have smoother contact points. This reduces the likelihood of scratching or denting sensitive components during handling or processing. This is particularly important in industries that require technical cleanliness or strict quality standards.

Resistance to Heat and Thermal Cycling

Woven wire mesh baskets perform exceptionally well in high-temperature environments. The woven structure allows the basket to expand and contract more evenly during thermal cycling, reducing the risk of distortion. This makes them a common choice for automotive manufacturing, heat treating, and annealing applications.

Corrosion Resistance

When fabricated from stainless steel or high-temperature alloys, woven mesh baskets offer excellent resistance to corrosion and oxidation. This ensures long service life even when exposed to aggressive chemicals, moisture, or extreme temperatures.

Comparing Welded Wire Mesh Baskets

Welded wire mesh baskets are valued for their rigidity and dimensional stability. They work well for lighter-duty applications where consistent shape is required and exposure to extreme conditions is limited. However, welded joints can become stress points over time, particularly in high-heat or heavy-load environments. Cracking at welds is a common failure mode when baskets are repeatedly exposed to thermal cycling or mechanical shock.

For operations that require long-term durability, airflow, and reduced maintenance, woven mesh baskets often outperform welded alternatives.

Common Industrial Applications for Woven Wire Mesh Baskets

Woven wire mesh baskets are used across a wide range of industries due to their durability and versatility. Common applications include:

- Industrial parts washing and degreasing

- Ultrasonic cleaning and rinsing

- Heat treating, annealing, and stress relieving

- Drying, curing, and coating processes

- Medical instrument cleaning and sterilization

- Food processing and sanitation environments

Many manufacturers pair woven mesh baskets with other material handling solutions such as custom wire baskets and racks designed specifically for their production workflows.

Customization for Your Specific Process

One of the biggest advantages of woven mesh baskets is their adaptability. Basket dimensions, wire diameter, mesh opening size, frame reinforcement, and material selection can all be customized to match specific parts and process requirements. This level of customization helps improve throughput, reduce part damage, and extend basket lifespan.

Custom fabrication also allows baskets to integrate seamlessly with conveyors, washers, furnaces, and robotic handling systems used in modern manufacturing facilities.

Choosing the Right Basket for Long-Term Performance

While both woven and welded wire mesh baskets have their place, woven wire mesh baskets are often the basket of choice for applications that demand durability, airflow, and thermal stability. Their ability to withstand harsh conditions while protecting valuable components makes them a smart long-term investment.

Work with a Trusted Wire Basket Manufacturer

Salco Engineering & Manufacturing has decades of experience designing and manufacturing custom woven mesh baskets for demanding industrial environments. From cleaning and heat treating to material handling and storage, Salco’s engineering team works closely with customers to deliver solutions that improve efficiency and reliability.

If you are evaluating basket options or need a custom-designed woven wire mesh basket for your operation, request a quote today to discuss your application with Salco’s team. A properly designed basket can improve process consistency, reduce downtime, and protect your parts at every stage of production.